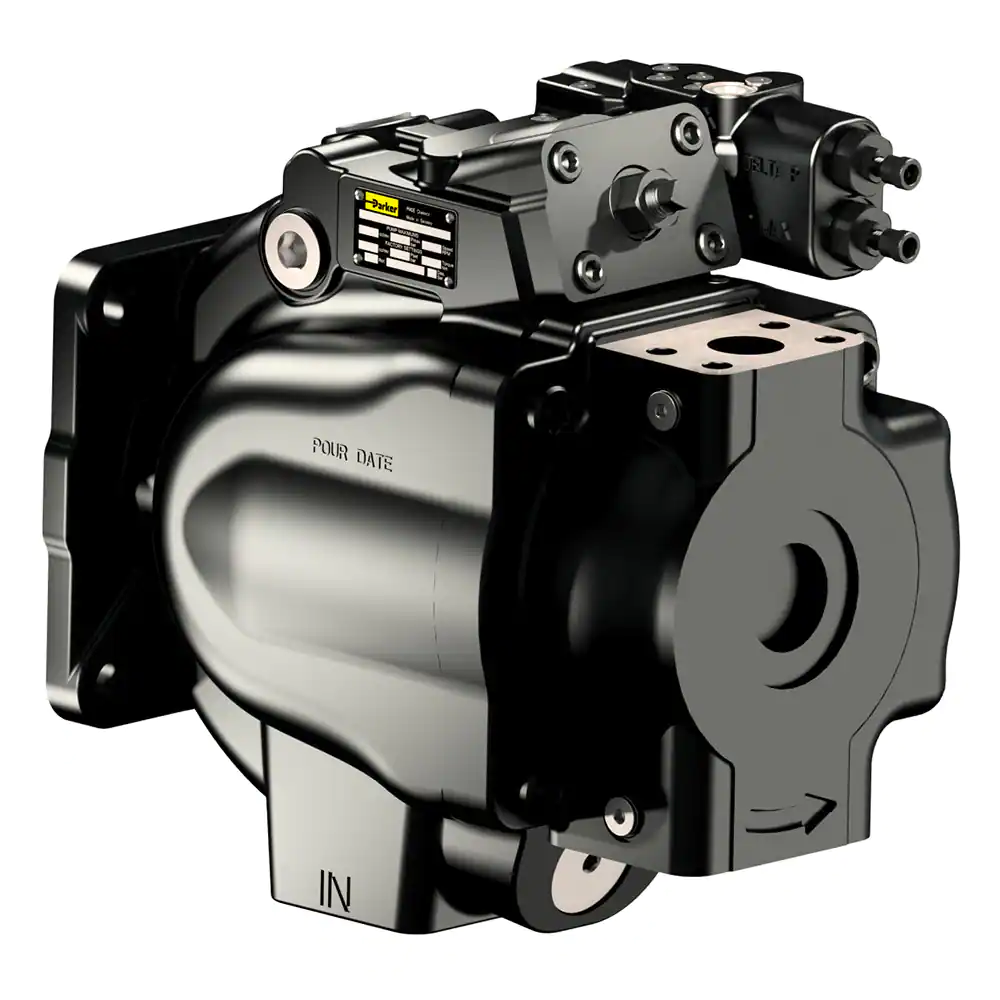

Parker P2060L00C1C18PA00N00T1A1P Mobile Pump

Parker P2060L00C1C18PA00N00T1A1P Mobile Pump is a general purpose pump used in vehicular and non-vehicular applications. It can be powered by an internal combustion engine, electrical power, or light-duty diesel engines.

Parker P2060L00C1C18PA00N00T1A1P Mobile Pump is a product for the customer in the oil or gas industry with requirements for mobility and high pressure. It is a modular, standardised, reliable pump used for transferring gas oil.

Feature:

1) We are an engineered pump system that integrates the functionality of a Parker P2060L00C1C18PA00N00T1A1P mobile pump into your chemical process system.

2) Helps in efficient transportation and storage of petroleum, petrochemical, and natural gas

3) The Parker P2060L00C1C18PA00N00T1A1P Mobile Pump’s robust and long-lasting construction makes for low life-cycle costs. As a result, businesses can invest in this pump knowing that it

4) This self-priming, high-capacity pump is designed to be simple and efficient. Parker P2060L00C1C18PA00N00T1A1P Mobile Pump

5) Parker P2060L00C1C18PA00N00T1A1P Mobile Pump is an industrial grade pump which can move liquid under pressure and has a wide range of capacities.

Parker P2/P3 series has been designed to meet the specific demands of heavy duty mobile applications. With continuous pressure ratings of up to 350 bar P2/P3 provides a high-power density and enables downsizing of mobile machinery. Optimized envelope and unique port layout ensure a fast and cost saving mounting on mobile transmissions. A wide range of options allows an adaption to the application specific needs.

The availability of both a standard (P2) and a supercharged, internally boosted version (P3) allows for high flow operation at the most diverse inlet conditions. As a standard every P2/P3 comes with an integrated pre-compression volume which ensures low ripple operation and reduced noise emissions.

Markets:

• Material Handling Equipment

• Construction Equipment

• Mining

• Water Drilling

• Forestry Equipment

• Agriculture Machinery

• Vocational & Municipal Equipment

• Other Mobile

• Defense

Benefits:

• High range of different displacements up to 145 cc/rev

• Operating pressures up to 350 bar (continuous)

• Various controllers like pressure, load-sensing and torque

• Self-priming speeds up to 2800 rpm

• Cost saving installation due to dedicated envelope design and unique port layout for direct mount on mobile transmission PTO’s

• Available as single pump or multi pump

• Integrated pre-compression volume – reduced pulsation and noise level

• Robust, heavy duty design

Applications:

• Material Handling Equipment like Reachstackers, Heavy Lift Trucks

• Construction Equipment like Mobile Cranes

• Mining like Wheel Loaders, Dump Trucks

• Water Drilling like Drill Rigs

• Forestry Equipment like Forwarders, Harvesters

• Agriculture Machinery like Harvesters

• Vocational & Municipal Equipment like Mowers

• Other Mobile

• Defense

For detailed technical information on P2/P3 pumps please download our latest catalogue and installation manuals under Product Support and/or contact your local Parker dealer for support.

* Made in Germany

Technical Specifications

| Pump Type | Piston, Variable |

| Body Material | Cast Iron |

| Configuration | Single, Multiple |

| Displacement | 60 to 145 cm3/rev, 3.7 to 8.9 inch3/rev |

| Operating Pressure | 320 / 350 bar, 4600 / 5000 psi |

| Flow Rate | 362 l/min, 79 gal/min |

| For Fluid Type | Standard Hydraulic Fluid, Synthetic Hydraulic Fluid, Fire Resistant Fluid, Biodegradable Fluid |

| Media | Hydraulic, Liquid |

| Maximum Operating Speed | 2200 to 2800 RPM |

| Minimum Fluid Temperature | -40 °F |

| Maximum Fluid Temperature | 115 °C, 239 °F |

| Weight | 37 to 78 kg, 81 to 172 lb |

| Shaft Type | SAE, DIN |

| Mounting Option | SAE |

| Port Type | Flange, Straight Threaded |

| Port Connection | SAE, ISO |

| Port Location | Side Ports |

| Direction of Rotation | Clockwise, Counter Clockwise |

| Circuit Path | Open Circuit |

| Sensor Type | No |

| Maximum Noise Level | 74 to 80 dBA |

| Drain Option | Yes |

| Filter Included | No |

| Radial Load Capacity | Consult Parker |

| Minimum Kinematic Viscosity | 10 cSt SUS |

| Maximum Kinematic Viscosity | 1000 cSt SUS |

| Thru-Drive Capability | Yes |

| Energy Recovery Capability | No |

| Control Method | Pressure, Remote Pressure, Load Sense, Torque Control |

| Charge Pump Included | Optional |

P2/P3 Series High Pressure Mobile Pump Document Download

![]() P2/P3 Series High Pressure Mobile Pump Service Manual

P2/P3 Series High Pressure Mobile Pump Service Manual