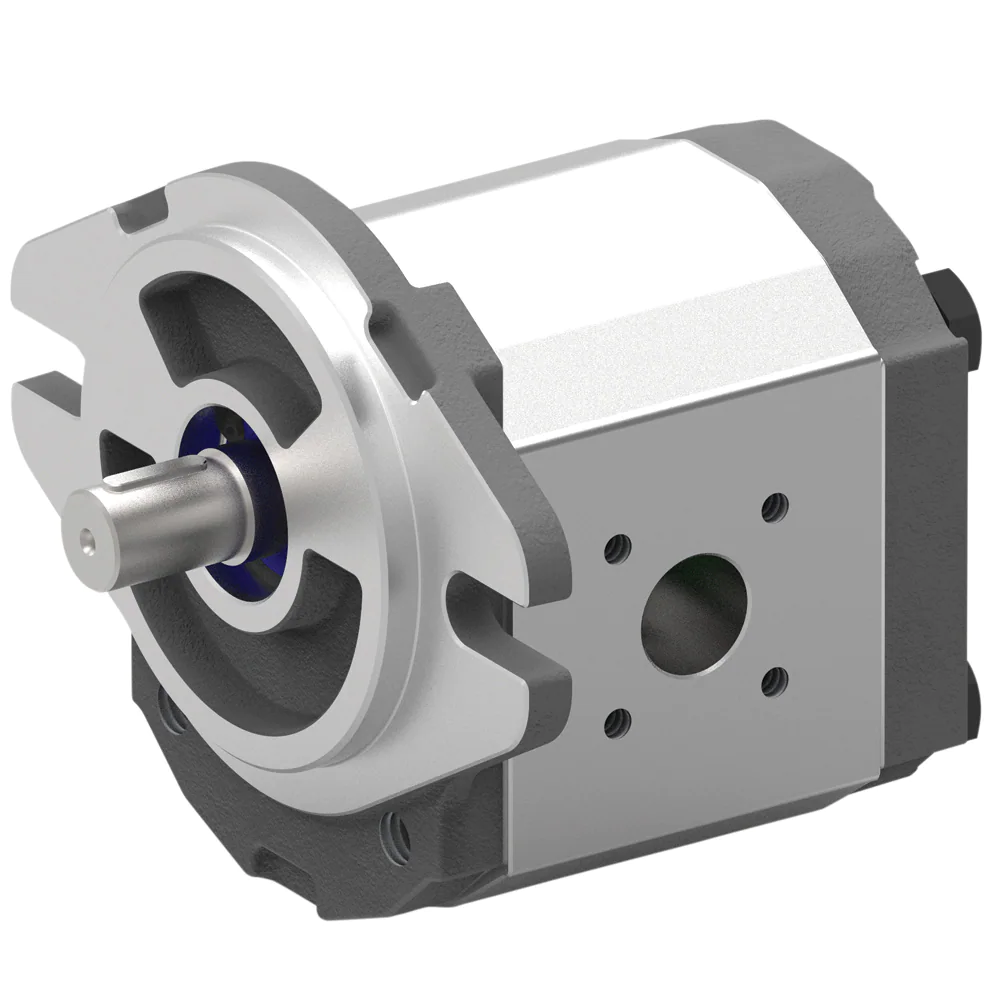

Parker 3339121330 |PGP517B0230CD1H3VE6E5S-517A016 Aluminum Pumps

The Parker 3339121330 pumps are perfect for anyone who needs to move fluids quickly and efficiently. These aluminum pumps are designed for use in a wide range of applications, and they’re built to last. With a durable construction and a variety of features, these pumps are an ideal choice for anyone who needs a reliable and efficient solution.

Get a quick quote

Parker 3339121330 |PGP517B0230CD1H3VE6E5S-517A016 Aluminum Pumps

These pumps have a high quality, lightweight construction, and a durable aluminum finish.

Aluminum Pumps are a metalworking machinery that can be used in an industrial setting. They are predominantly used for tasks such as drilling and forming.

Feature:

1) Parker 3339121330 |PGP517B0230CD1H3VE6E5S-517A016

2) Parker 3339121330 | PGP517B0230CD1H3VE6E5S-517A016 Aluminum Pumps are of the highest quality and come with a lifetime warranty against manufacturing defects.

3) Connects to a variety of pressure sources, which makes it perfect for use as a vacuum pump.

4) Parker 3339121330 |PGP517B0230CD1H3VE6E5S-517A016 Aluminum Pumps can be used in a range of applications including hydraulic systems, industrial process equipment and chemical manufacturing

5) The Parker 3339121330 | PGP517B0230CD1H3VE6E5S – 517A016 Aluminum Pump is a robust, high-pressure pump that is an excellent choice for industrial applications.

Parker’s Aluminum Pump PGP517 Series fixed displacement gear pump offers high performance and high power density dues to its aluminum construction, making it an ideal selection for the Aerial, Agriculture, Construction, Forestry, Material Handling, and Turf Equipment markets. It is available as a standard pump, clutch pump, tandem pump or as a pump with a priority flow valve including primary circuit relief valve.

Markets:

• Aerial

• Agriculture Machinery

• Construction Equipment

• Forestry Equipment

• Material Handling Equipment

• Turf Equipment

• Vocational & Municipal Equipment

Benefits:

• Three-piece construction for distribution flexibility

• Aluminum pumping sections for light weight

• Journal bushings for long life

• Pressure balanced thrust blocks for high efficiency

• Multiple sections available

Applications:

• Power steering pumps – priority valves available

• Brake pump

• Brush Chipper

• Trencher pump

• Hydraulic Power Unit

• Aerial Lift

• Transfer pump

• Lube pump

Technical Specifications:

• Sizes from 16 to 70 cc

• Operating pressures up to 275 bar (3,988 psi)

• Speeds up to 3,400 rpm

• CW, CCW, and Bi-rotational pumps available

• SAE shafts, flanges and porting available

For detailed technical information on PGP517 please download our latest catalogue and installation manuals under Product Support and/or contact your local Parker dealer for support.

*Made in Czech Republic

Technical Specifications

| Pump Type | Fixed |

| Body Material | Aluminium |

| Configuration | Single | Tandem | Multiple |

| Displacement | 16 to 70 cm3/rev, 0.09 to 4.27 inch3/rev |

| Operating Pressure | 250 bar, 3625 psi |

| Flow Rate | 168 L/min, 44.35 Gal/min |

| For Fluid Type | Standard Hydraulic Fluid |

| Maximum Operating Speed | 3400 RPM |

| Minimum Fluid Temperature | 15 °C, 5 °F |

| Maximum Fluid Temperature | 80 °C, 176 °F |

| Weight | 41 kg, 30.8 lb |

| Shaft Type | SAE | ISO | DIN | Industry Specific |

| Mounting Option | SAE | ISO | DIN |

| Port Type | Flange | Straight Threaded |

| Port Connection | SAE | ISO | BSPP | ODT |

| Direction of Rotation | Clockwise | Counter Clockwise |

| Circuit Path | Open |

| Thru-Drive Capability | Yes |

PGP517 Series Aluminum Pumps Document Download

Related products

-

PGP517 Series Aluminium Pumps

Parker 3339121307 |PGP517B0330CD1H3NP4P3S-517A033 Aluminum Pumps

Rated 0 out of 5Read more -

PGP517 Series Aluminium Pumps

Parker 3339121306 |PGP517B0250CD1H3NE7E6C-517A016 Aluminum Pumps

Rated 0 out of 5Read more -

PGP517 Series Aluminium Pumps

Parker 3339121300 |PGP517B0520CD1H3NP5P3S-517A038 Aluminum Pumps

Rated 0 out of 5Read more -

PGP517 Series Aluminium Pumps

Parker 3339121293 |PGP517B0190CD1H3NJ9J8S-517A019 Aluminum Pumps

Rated 0 out of 5Read more