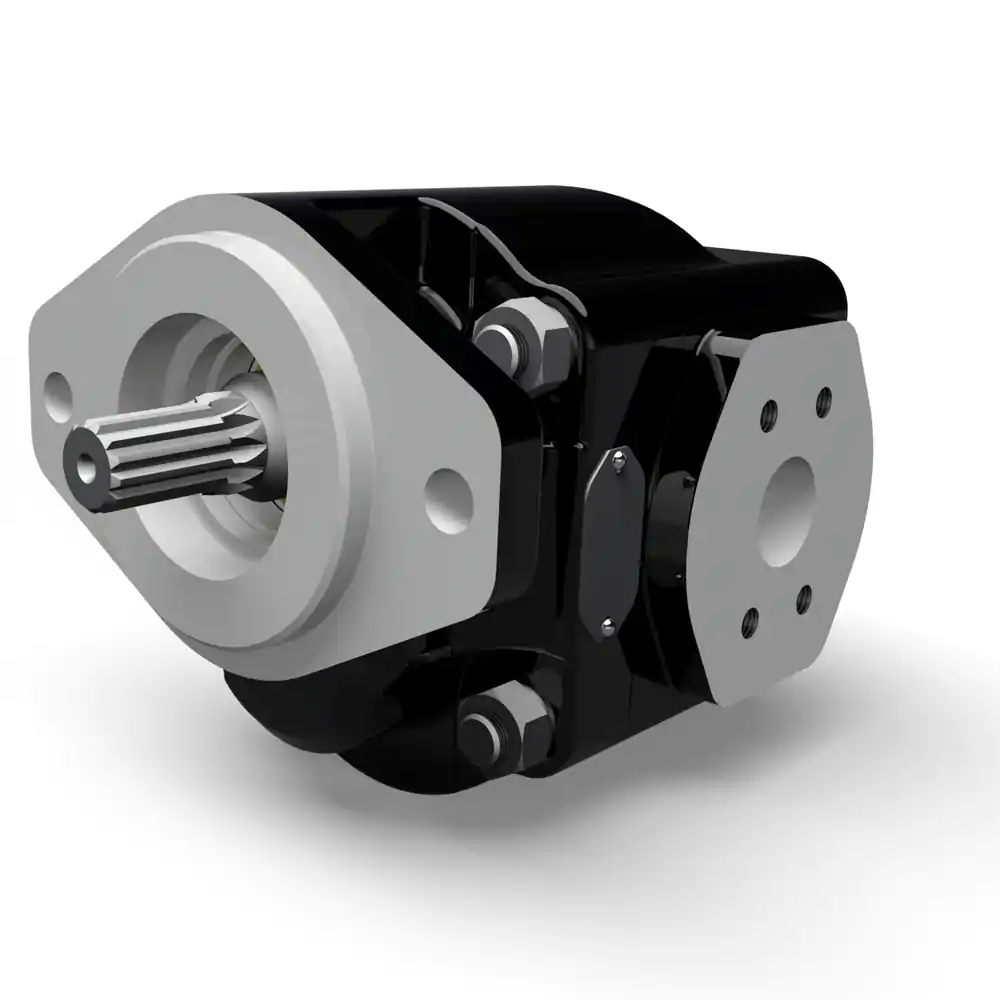

Parker 7049112008 |PGP640A0800AE4A4NT6T4B1B1 Cast Iron Pumps

The Parker 7049112008 | PGP640A0800AE4A4NT6T4B1B1 is a cast iron pump that is specifically designed for use in engineering applications. This pump is made from high-quality materials and construction, and it is able to withstand the rigors of industrial use. The pump features a durable design that will provide years of reliable performance.

Get a quick quote

Parker 7049112008 |PGP640A0800AE4A4NT6T4B1B1 Cast Iron Pumps

This product is an engineered version of a standard Parker 7049112008

Our Parker 7049112008 |PGP640A0800AE4A4NT6T4B1B1 cast iron pumps are designed to withstand the toughest of environments. Our pumps are manufactured with the highest quality components, and can be customized for your specific needs.

Feature:

1) The Parker 7049112008 PGP640A0800AE4A4NT6T4B1B1 cast iron pump is very strong and can withstand high pressure.

2) Parker 7049112008 |PGP640A0800AE4A4NT6T4B1B1 are cast iron pumps and are a high efficiency pump.

3) Parker Pumps are designed to reliably pump slurry for more than 50,000 hours. The Parker PGP 640A0800AE4A4NT6T4B1B1 cast iron pumps are widely used in mining, slurry systems

4) Parker 7049112008 |PGP640A0800AE4A4NT6T4B1B1 Cast Iron Pumps have a long-lasting, durable construction and can withstand the harshest environments.

Parker’s 600 Series two-piece flange body combination requires less space for the pump/motor, allowing for greater ease of installation in tight areas, which lowers OEM assembly labor costs. Parker’s 620 series is a type of fixed/positive displacement gear pump that offers the most volumetrically efficient and power dense solution due the interlocking, two-piece cast iron design, making the 600 series ideal for engineered mobile equipment solutions demanding energy efficient, high performing hydraulic systems. The 600 series is widely used in the most demanding applications such as Construction, Material Handling, and Military. They are available as single or multi-section pumps with pressure relief, and anti-cavitation.

Markets:

• Agriculture Machinery

• Construction Equipment

• Forestry Equipment

• Material Handling Equipment

• Turf Equipment

• Mining

• Oil & Gas

Benefits:

• Two-piece, interlocking body construction for high efficiency and high pressure

• Cast iron pumping sections for durability

• Journal bushings for long life

• Pressure balanced thrust plates for high efficiency

• Multiple sections available

Applications:

• Fan drive pump

• Mower pump

• Steering and brake pump

• Winch pump

Technical Specifications:

• Sizes from 19 to 50cc

• Operating pressures up to 275 bar (4,000 psi)

• Speeds up to 3,500 rpm

• CW, CCW, and Bi-rotational pumps available

• SAE shafts, flanges and porting available

• Extensive valve options available: Pressure relief, anti-cavitation, cross port relief, solenoid unloading, and proportional relief.

Technical Specifications

| Operating Pressure | Up to 3989 psi, Up to 275 bar |

| Flow Rate | NA |

| Displacement | Up to 50 cm3/rev, Up to 3.1 inch3/rev |

| Body Material | Cast Iron |

| Drain Option | No |

| Charge Pump Included | No |

| Circuit Path | Open |

| Configuration | Single / Tandem / Multiple |

| Control Method | Relief, Load Sense, Priority, Unloader |

| Energy Recovery Capability | No |

| Filter Included | No |

| For Fluid Type | Standard Hydraulic Fluid / Phosphate Ester / Water Glycol |

| Maximum Displacement | 50 cm3/rev, 3.1 inch3/rev |

| Maximum Flow Rate | n/a |

| Maximum Fluid Temperature | 80 °C, 180 °F |

| Minimum Fluid Temperature | -20 °C, 0 °F |

| Maximum Operating Pressure | 275 bar, 3989 psi |

| Radial Load Capacity | Consult Parker, Consult Parker lb |

| Maximum Operating Speed | 3500 RPM |

| Maximum Kinematic Viscosity | 7500 SUS |

| Minimum Kinematic Viscosity | 50 SUS |

| Weight | 13.3 kg (Max), 29 lb (Max) |

| Media | Liquid |

| Mounting Option | SAE | ISO | DIN |

| Port Connection | SAE | ISO | NPT | BSPP | ODT |

| Port Type | FLANGE | STRAIGHT THREADED | |

| Port Location | Side Ports | Rear Ports |

| Pump Type | Gear, Fixed |

| Direction of Rotation | Clockwise | Counter Clockwise | Bi-Rotational |

| Shaft Type | SAE | ISO | DIN | Industry Specific |

| Thru-Drive Capability | No |

PGP600 Series Cast Iron Pumps Document Download

Related products

-

PGP 600 Series Cast Iron Pumps

Parker 7049112028 |PGP640A0600AE4A6MS6S3B1B1 Cast Iron Pumps

Rated 0 out of 5Read more -

PGP 600 Series Cast Iron Pumps

Parker 7049112027 |PGP640A0550AE1H3NT5T3B1B1 Cast Iron Pumps

Rated 0 out of 5Read more -

PGP 600 Series Cast Iron Pumps

Parker 7049111124 |PGP640A1000CE4A4NE8E8B1B1 Cast Iron Pumps

Rated 0 out of 5Read more -

PGP 600 Series Cast Iron Pumps

Parker 7049111123 |PGP640A0500CE4K3NT5T3B1B1 Cast Iron Pumps

Rated 0 out of 5Read more