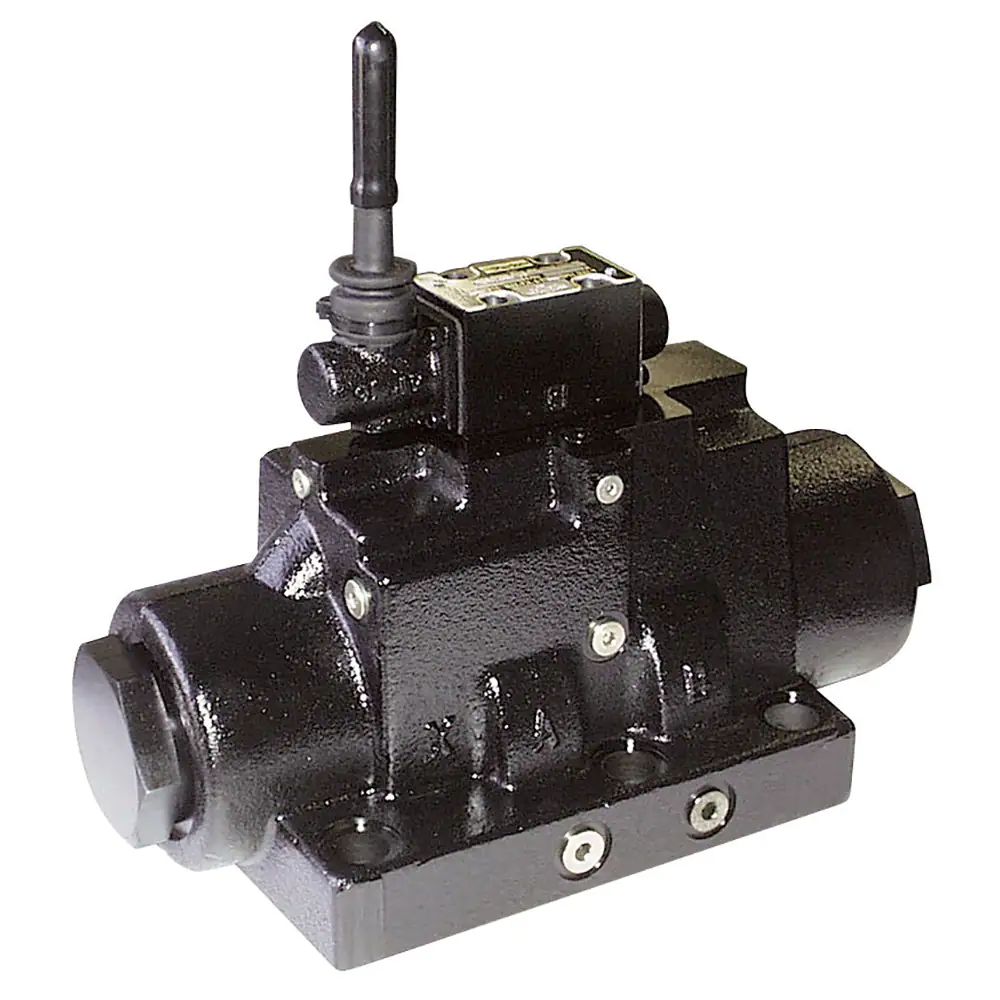

Parker’s D101VL directional control valves are available in 2 or 3-position styles. These valves are manifold or subplate mounted which conform to NFPA’s D10, CETOP 10 mounting pattern.

Markets:

• Entertainment Automation

• Factory Automation

• Lumber & Wood

• Machine Tools

• Marine

• Material Handling

• Miscellaneous Industrial

• Miscellaneous Manufacturing

• Miscellaneous Processing

• Molding

• Oil & Gas

• Other Natural Resources

• Packaging Machinery

• Plastic Packaging

• Power Generation

• Primary Metal Refining/Process

• Printing and Marking Equipment

• Rubber & Tire Processing

• Vehicle Assembly Facilities

Benefits:

• Low pressure drop design

• Low force required to shift spool

• Hardened spools provide long life

Applications:

• Suitable for general hydraulic applications

Technical Specifications

| Maximum Operating Temperature | +140 |

| Maximum Flow Rate | 130, 250 |

| Minimum Operating Temperature | -4 |

| Actuation Type | Lever Operated |

| Body Material | Grey Iron |

| Seal Material | Nitrile, Fluorocarbon |

| Valve Type | Lever Operated Directional Control Valve |

| Size | NFPA D08, CETOP 8, NG32 |

| Maximum Operating Pressure | 3000 psi, 207 bar |

| Mounting Type | Subplate |

| Weight | 77.2 lb, 35 kg |

Parker D101VL Series Lever Operated Directional Control Valve Service Manual

![]() Parker D101VL Series Lever Operated Directional Control Valve Service Manual

Parker D101VL Series Lever Operated Directional Control Valve Service Manual

Related products

-

Hydraulic Valves

Parker VPL Series Pressure Compensated Directional Control Valve

Rated 0 out of 5Read more -

Hydraulic Valves

Parker D1FC / D3FC Series Direct Operated Proportional Directional Control Valve

Rated 0 out of 5Read more